Haven't had a chance to post much lately, been pretty busy either working or getting the oval back together. Progress has been marred a little by real work, which has taken me out of Adelaide, this has meant that work on the oval comes to a complete standstill (there is only me unfortuantely). Looking at the countdown time on my widgets, it's telling me 21 days to go, not a lot of time, but still lots to do. Since getting the pan back from the cage builder, I've been busy getting the suspension and steering back together, and also getting the scatter shield made up.

The scatter shield has probably been the biggest headache of all - not only does it have to be custom made, but i also had to figure out how to mount the 915 gearbox in as well - double trouble. I started off making a simple hoop out of flat bar which I was going to mount to a beefed up trans support, but this didn't look strong enough. Then, whilst helping the father in law with his Triumph Bonneville I spotted a prime mover brake drum, that he said he had used as a brazier - perfect size, but unfortunately cast iron and not suitable. He called me back a few days later to say that he had found a rolled steel extension that was made for the top of the brazier - he dropped it over and work started on scatter shield mark 2.

The scatter shield needs to be 6mm thick steel, and whilst there are not any actual reccomendations in the DLRA rules, general consensus within the drag racing fraternity is that it should extend 1 1/2" forwards and back of the flywheel. For the V8 guys this is easy - just go to your local speed shop and order a replacement bell housing for your trans - job done. Unfortunately, the Porsche (or VW) box is all one piece and so this simply isnt an option.

The rolled steel I got from the father in law (cheers Chris) was a litttle too big in diameter, so I had to cut a section out and then use ratchet straps to close up the gap before re-welding it. it's not the prettiest of jobs, but without a set of rollers, it's a hard thing to fabricate.

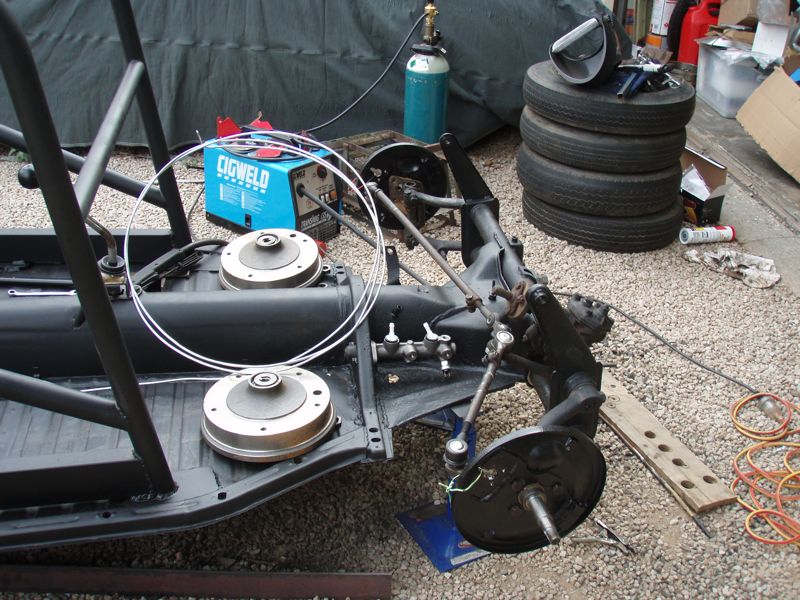

With the scattershield done, and the pan painted with a generous coating of gloss enamel underneath and matt enamel on top, with some POR 15 on the exposed front and rear frames , the refit has started. the front and rear suspension are now back on, and the brakes are next on the list - everything is new, so hopefully it's a case of reassemble rather than rebuild.

The gearbox is officially in. The shift rod has been shortened and gears have been selected - I modded a repro hurst shifter to work with the 5 speed box, had to bend it a little to prevent my knuckles grazing the roll cage, and ideally would like to add spring gates to it, but I will leave this as a last on the list job, as currently I can select gears.

The schedule is now really out of whack, but 3 weeks is still time enough if I knuckle down - it takes about 2 weeks to reassemble a car including trim and this doesnt have anything inside at all. Need to get the body back on to clearance for the engine, and also see if the extra 25mm I managed to push the gearbox further forwards will now allow the stock deck lid to close. If not I managed to source a cheap semi-w to cut a hole in for the Porsche fan.

Off to get the brake shoes relined tomorrow, then I can get the pan rolling again.

Fingers crossed.....

There's heaps more pics in the gallery - just search for the tag vdubber - http://www.vdubber.com/photo/gallery_tag/vdubber/50/1