By

Mick

From album Supercharged 1600 Project

From album Supercharged 1600 Project

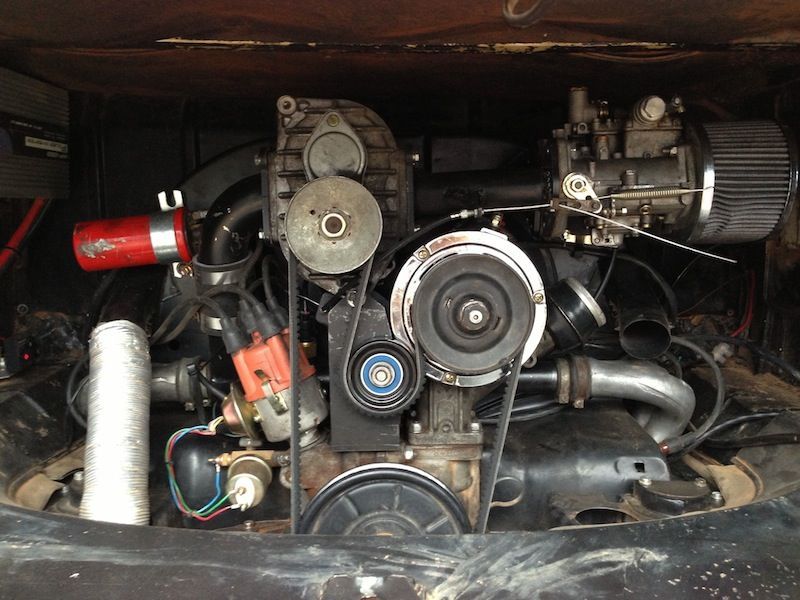

Don't try this at home kids. Test run in controlled conditions ;)

12 July 2014

·

11 years ago

From album Supercharged 1600 Project

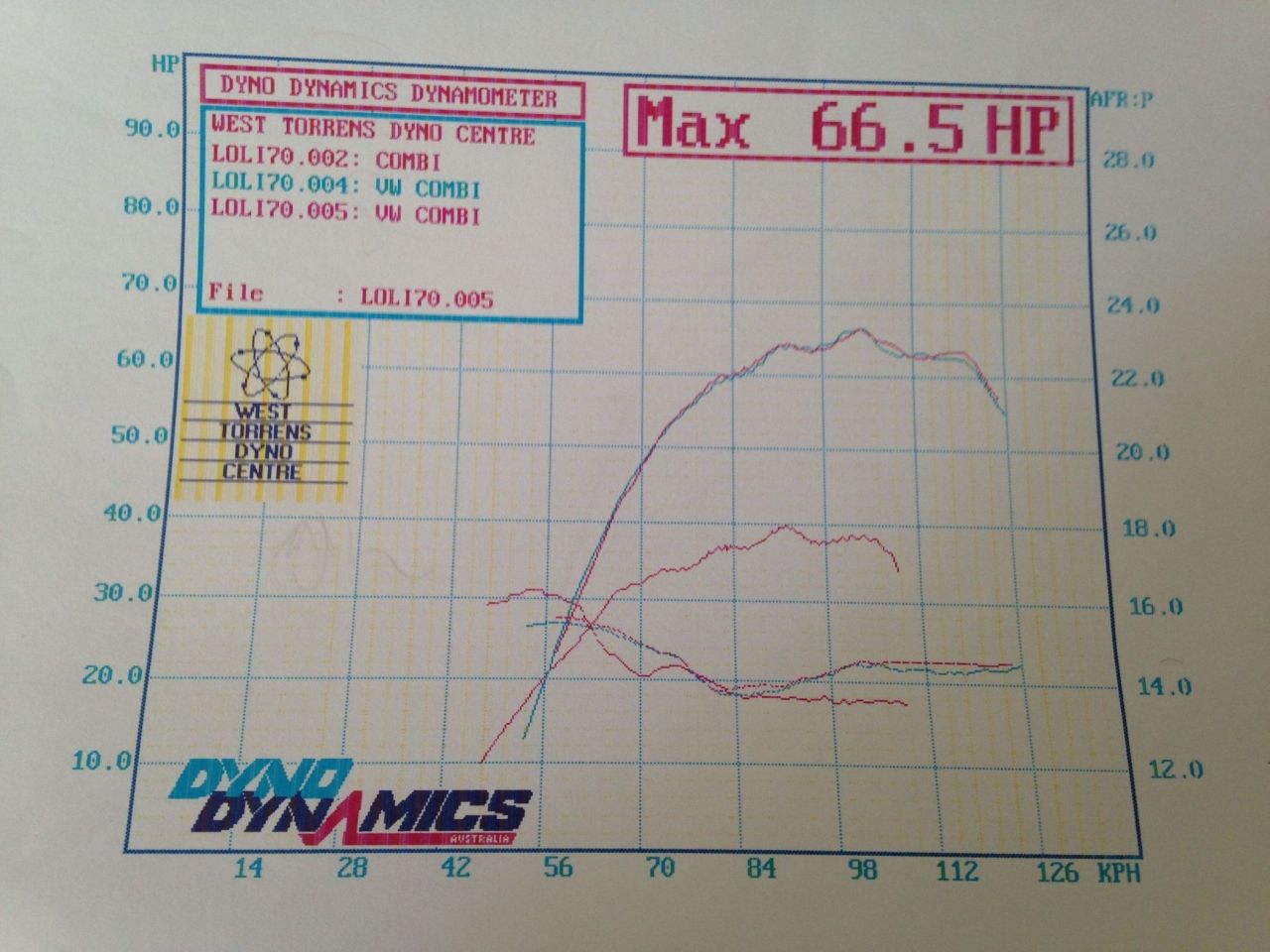

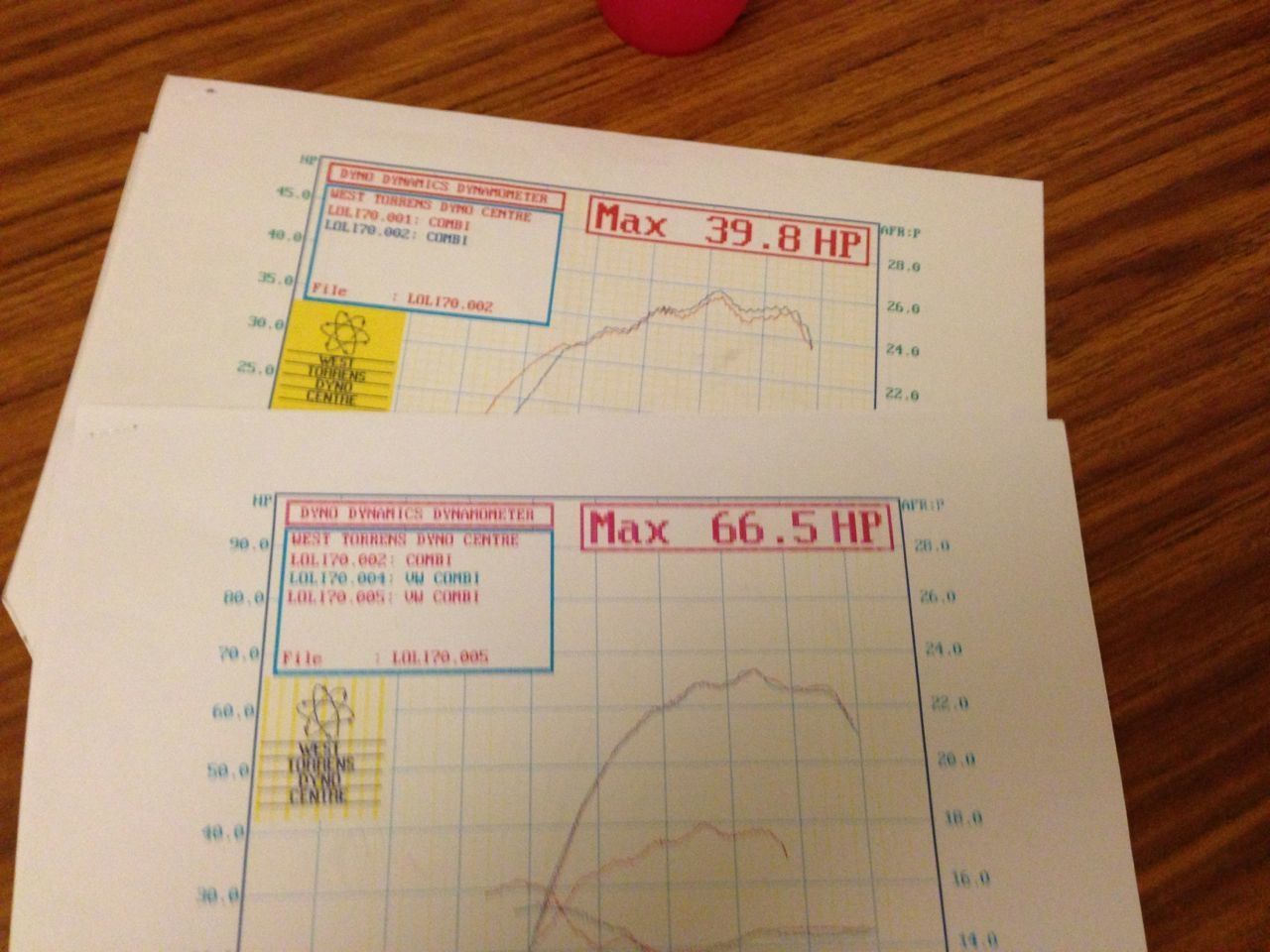

Dyno readings at 4/5psi. Approx 77hp at flywheel. Bus is now running 6/7psi so really need to pay another visit to the dyno.

22 May 2013

·

11 years ago

From album Supercharged 1600 Project

From album Supercharged 1600 Project

The finished article - this thing is tiny.

22 March 2013

·

12 years ago

From album Supercharged 1600 Project

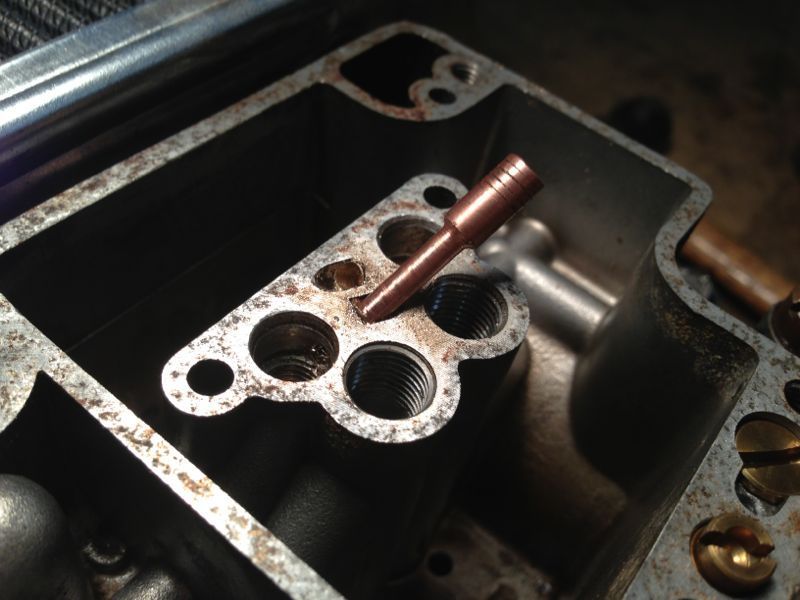

The idle air bleed circuit is counter-bored and the insert will be pressed in place - kinda like this

22 March 2013

·

12 years ago

From album Supercharged 1600 Project

From album Supercharged 1600 Project

Turning down an insert to plug up the air bleed circuit in the Dellorto DHLA 40H Carby

22 March 2013

·

12 years ago

From album Supercharged 1600 Project

Shredded belt. Forgot to tighten idler pulley and it moved up against alternator pulley shredding the belt. :(

21 March 2013

·

12 years ago

From album Supercharged 1600 Project

Air bleeds on emission model DHLA's are fixed at 2mm (two small holes in centre). Might need to sort these out.

21 March 2013

·

12 years ago

From album Supercharged 1600 Project

From album Supercharged 1600 Project

From album Supercharged 1600 Project

From album Supercharged 1600 Project

From album Supercharged 1600 Project

Some time later and I've turned the pulley I found into a new supercharger pulley.

20 March 2013

·

12 years ago

From album Supercharged 1600 Project

This is the cause of my belt slip - wrong pulley profile. The pulley supplied with the supercharger is for an A profile belt not a vee belt It's the same kind of pulley as you find on lathes, mills and various machines NOT cars.

20 March 2013

·

12 years ago

From album Supercharged 1600 Project

Scored this pulley at the local machine shop - 80mm diameter

20 March 2013

·

12 years ago

From album Supercharged 1600 Project

Selection of pulleys - from left to right - random pulley that came in a box of junk with my mill, VW A/C pulley, AMR 500 pulley, Stock VW crank pulley

20 March 2013

·

12 years ago

From album Supercharged 1600 Project

Drilling out the jets on the Dellorto. These drills are tiny - the smallest one is 0.3mm

19 March 2013

·

12 years ago

From album Supercharged 1600 Project

From album Supercharged 1600 Project

My temporary second idler pulley - free vice grips with every kit

17 March 2013

·

12 years ago

From album Supercharged 1600 Project

Got another clearance issue - bit too close to the alternator connection for my liking. This is an easy fix tho

17 March 2013

·

12 years ago

From album Supercharged 1600 Project

Had to add a second idler pulley as the belt was flapping a bit on the un driven side. Still not 100% so looks like I will need to use a sprung pulley. Really hoping to keep the stock pulleys but will have to see if I can fix the slip and also...

Had to add a second idler pulley as the belt was flapping a bit on the un driven side. Still not 100% so looks like I will need to use a sprung pulley. Really hoping to keep the stock pulleys but will have to see if I can fix the slip and also how the belt holds up

More

From album Supercharged 1600 Project

From album Supercharged 1600 Project

From album Supercharged 1600 Project

Design flaw - the vac can on the SVDA is a gnats codgers from the drive belt. Will need to address this on the final version.

16 March 2013

·

12 years ago

From album Supercharged 1600 Project

Modifying the SVDA to limit the overall advance. Normally most people opt to bend the tabs in to lock out the dizzy. I opted to drill and tap the tabs so that I could fit grub screws and 'dial in' the overall advance to suit the application.

16 March 2013

·

12 years ago

From album Supercharged 1600 Project

No photos available

Drop a file here to upload.