36hp Challenge K36 Build Progress

A short time ago I posted about changing direction with the oval and entering into the K36 class of the 36hp challenge with a blown 36hp engine. Since that time I've been carefully planning the build and collecting the necessary parts.

The build has changed a bit since the initial plans with the stroke being increased to 72mm and the bore now at 83.5 which gives just over 1600cc. This is good in one respect as it is a capacity that is familiar to me with the Joe Blow kits - it gives me a bit of confidence that I know I can get the setup to perform pretty well. The only drawback is that it pushes me up into the next engine size category in the DLRA class system - at the lower capacity end of that class too. This will make getting a DLRA class record a lot harder but not altogether impossible.

At the moment I'm waiting for my crank and heads to arrive, once I have these I will set about getting some forged pistons made up. I have some Mahle pistons that were supplied with the 40hp big bore 83.5 barrels but I want to run forged pistons as I'm planning on some higher than normal boost. Unfortunately until the heads get here I don't know what cc they are so cannot calculate the CR. I also want to trial assemble the engine with the Mahle pistons so that I can check out the skirt clearance from the crank.

The heads I'm using are Wolfsburg West Okrasa copies. These are being put together by Brothers and will feature 35mm x 32mm stainless valves, uprated springs and a nice port job. I'm also having the heads drilled for a second spark plug - this is to assist with potential detonation issues at the higher boost.

The crank is a DPR welded and offset ground unit made from a 36hp core. I would have loved to have used the new AA Chromoly 914 72mm crank but it's just too expensive for this build. Cam is stock 36hp. I have a very nice low k's cam that I will use long with a set of 1.4:1 speedwell ratio rockers, I also indulged in a pair of speedwell rocker covers as well.

I've managed to source most of the parts for the build including most of the EFI system, including the ECU (megasquirt) twin wasted spark coil packs, injectors and manifolds

Twin ford style coil packs. I need to make a small modification to the megasquirt to be able to run these directly from the ECU - a pretty easy mod to do. I will also upgrade the MAP sensor to a 2 or 3 bar unit. The stock 1 bar unit supplied with the megasquirt will not be big enough.

Cleaned and matched Bosch injectors - these are 20cc units which should be good for up to 160hp - way higher than I will achieve.

I also indulged myself and bought a decent boring head so that I can clearance the case for the larger barrels. The 40 horse 'big bore' barrels require the case to be opened up to fit. I also experimented with 50 horse 85.5mm barrels, which can be made to fit but do not leave very much material to hold the head studs.

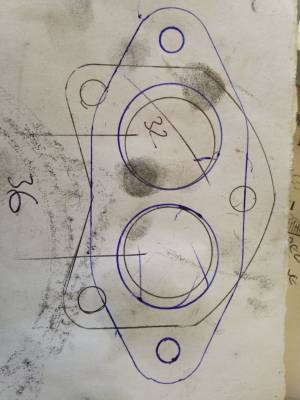

The inlet manifolds that I will be using are stock 50 horse items. The stock inlet ports are very similar in size and location to the Okrasa ports - in fact it's pretty easy to see where VW might have got the idea for the twin port. I'm hoping that with the port job on the heads there will be only minimal blending to carry out.

Along with the crank I have also ordered a 36hp flywheel with 200mm clutch and 12 volt ring gear along with a stage 1 Kennedy clutch and apart from the aforementioned pistons the only other item I need to source is a 1 1/2" merged header. I already have a 1 5/8" header but thinking that this is maybe a little too large. Again I will wait for the heads to arrive and find out what size ports they have before ordering another.

Next steps are to get the body reassembled and finshed off whilst I wait for the engine parts to arrive. I've still got to bolt the body to the pan and refit the wings. I also need to sort out the windows and make up some interior panels. Lots to do and only a few months to do it in.

Comments