Okrasa 1625cc

Been a bit flat out with work so no real time to do anything on the build but have been doing a bit of daydreaming whilst standing at the lathe. I've somehow convinced myself that I should put together my Okrasa engine for the Speedster.

Back in 2016 I raced my Oval at Speedweek at Lake Gairdner here in South Australia. At the time it was running a 1600 single-port industrial engine with one of my blower kits on it and I managed to come home with a record. This engine choice was not the original plan for the Oval, but unfortunately I ran out of time to finish the planned engine for that particular season. I was half way through building a 'big bore' 36hp engine for the 36hp Challenge. This engine was based on a 74mm stroke Porsche 912 crank with oversized 40hp 'big bore' 83.5mm barrels and pistons and modified Okrasa heads. The original plan was to fit an AMR500 blower to it along with EFI and try and get my 100 mph hat and set an all out record. But whilst I did manage over 100 miles per hour that week, I did not earn my '1' hat as this was only for 36hp based engines. This was not really an issue as I'd been building the car off and on since 2009 and the engine for almost as long. I had planned to return in 2017 with the Okrasa engine but unfortunately, shortly after returning from Speedweek I was rear ended in a car crash which ruptured one of the discs in my neck, and so racing was not high on my agenda. Struggling to be able to do anything the engine just got left on the shelf in the garage which is exactly where it's been sitting for the past 5 years, unloved and untouched.

Fast forward to today, March 2021, and I've been thinking about what kind of engine to fit into the Speedster. I've got a fair collection of engines, and also heaps of parts to make engines. There's a 2.7 Type 4, a 1776, three or four 1600's the start of an oxyboxer project, boxes of various parts and of course the Okrasa engine that was originally destined for the Oval. The Type 4 is one possibility and would make for a pretty exciting drive, but I really want to save this for my 15 window. I built the Type 4 over 20 years ago for my Type 34 as I intended to race it on weekend track days, but after I moved to Australia I ended up building and installing a 2180 for it instead as there's no real racing scene for classics here like in the UK. This lack of racing scene is what put me on to Land Speed Racing. The Type 4 was going to be the next engine in the Oval as the plan was to run the Okrasa engine for a season, get my 1 cap and then install the Type 4 and go for all out speed, but as a result of the accident I've retired from racing and sold the Oval and so the engine just sits there patiently waiting for me to get the 15 Window on the road.

The 1776 is another contender, and it may yet end up in the Speedster. I started building this engine as the ultimate AMR500 engine, with the goal being to see how much power I could make from one of my kits and cams. this is a bit like the oxyboxer, where it's not being built for any particular car but just because I like building engines. However I figure that I probably want to start off with something a bit more pedestrian first, which leaves one of the 1600's or the Okrasa engine, The 1776 might also end up in my '55 panel van - the Joe Blow Delivery bus as the overall idea is a sign-written bus with one of my kits installed - a promotional vehicle of sorts.

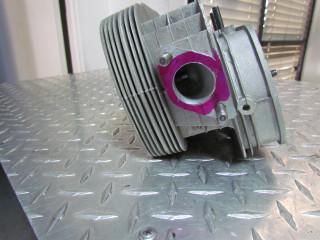

The Okrasa engine is also kind of period correct for the Speedster. It's a 36hp engine which is essentially the same case used in Pre-A's. The Okrasa heads are very similar to the standard late model 1600 VW head. (It's easy to see where VW got their design inspiration from). The early Porsches also shared the dual-port configuration and whilst the Porsche heads are a little bit different they are visually similar. I also have a few pairs of Webers and Dells laying about which would again make a visually similar engine to the Porsche dual port 36hp based engine. Of course the finer details would be different but then it's not supposed to be an exact replica plus a contemporary power plant would really complete the overall driving experience.

So I've been pondering building up the Okrasa engine as a 'Vintage Speed' engine as it would look right at home installed in the Speedster, but one of the stumbling blocks was that I had the heads machined for a second plug, which really requires either EFI or at a minimum one of my Ignition systems to control. This is unfortunately not going to be very 'Vintage Speed' looking. Having gone to the trouble of adding the second plug it definitely needs to be used. Plus it's in line with the twin plug Furhmann engines of those early Carreras and would make a similar sound (the sound of twin spark is quite distinctive). I could, of course just not connect the second set of plugs, but where's the fun in that? So I've decided to use my ignition setup to control the dual spark setup. Plus this gives me an opportunity to do some further R&D on the Ignition system.

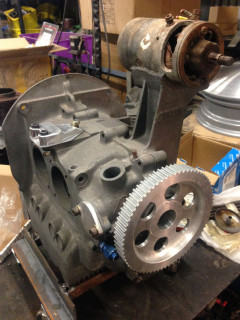

After deciding that I would definitely use the Okrasa engine I started to collect a few parts. I bought a nice O/T Porsche crankshaft pulley and a Fram style oil filter setup but realised that the 356 crank pulley is not the best option for adding a trigger wheel to, so I need another option. A distributor driven trigger is out of the question as it's simply too low a resolution signal and too unrepeatable. Which only really leaves flywheel trigger, I'm down with that, nice and stealthy and an option that I've considered many times as it's similar to the set up on my Range Rover. So today I dug out the stack of parts for the build and had a bit of a measure up. I originally had a custom flywheel made up using a 200m clutch, 12v ring gear and the 36hp hub. It's already had a lot of material removed from the outer diameter when it was lightened so with a nice 200mm diameter trigger wheel mounted to the backside of the flywheel the teeth will just stick out clear of the metal. This diameter also puts the sensor in a nice easy to mount position too.

Okay, so that's taken care of the spark control, but do I really want to run modern coil packs? They are not very 'Vintage Speed' looking. Originally I bought two Ford coil packs which are very modern looking. I considered fitting a dummy distributor and hiding the coil packs behind the fan shroud, but that's laughable really. For a truly Vintage Speed look I decided that I need to retain a distributor so I started to look at dual spark distributors. I know I am am a massive advocate for throwing distributors in the bin but this is an odd exception where aesthetics must prevail. The Aussie Pobjoy twin spark engines used a Datsun dual spark distributor cap mounted to a modified 009. I did a bit of a search on this and found that Datsun had made a few dual spark engines, of note was the 200SX. So I've ordered a 200SX distributor cap and rotor. The plan is to make a distributor to fit the rotor and cap. There's no need to have points installed in it as the ECU takes its trigger from the flywheel trigger wheel and will control the two coils directly. So I just need to make a simple shaft and housing that contains a shaft and the rotor. I'll copy the bottom dimensions for the stock VW dizzy and add a suitable top-plate to take the cap. Easy stuff really if you have a lathe.

I had to make a compromise on the coil packs however. I managed to source some TO-3 style IGBTs (old school looking transistors) with the intention of making an electronic ignition from them. This would allow me to take the ECU signal and drive a regular oil filled coil which I could then dress up to look like a judson magneto with the IGBTs mounted on a nice looking heat sink. But the more I thought about this, the more I decided that this was really a compromise I did not want to make. Modern coil packs are so much more efficient and run so much better. So I found a couple of transformer style smart coils that I figure I could make a period looking case for. The plan is to add a funky looking heat sink to the unit and make it look like a period CDI set up.

The last issue that I needed to solve was the cam. Originally the engine was going to be blown. Back in 2016 I had spoken to Johannes Person at JPM Motorsport about getting a custom 36hp cam ground and having been so invested in this build back at that time there's a part of me that still wants to stick a blower on the engine. But this also carries its own issues to solve, not least that adding a blower to the engine means that I could not use that lovely O/T crank pulley or fit the Fram oil filter or the dual carbys and then all of a sudden it stops looking like a vintage speed engine.

So I've decided the engine is definitely going to be N/A. and so I've decided to run a Wolfsburg West cam. These are the most accessible and if I recall are based on an Isky grind. I also have the Speedwell 1.4:1 ratio rockers that I originally purchased along with a custom dual spring setup and a set of backline racing lifters. Ideally the inlet ports could probably do with a little more work for an N/A setup but again I think I'll leave as-is.

This leads me on to the next issue; the heads. The heads were prepped for a blown application and have a 48cc chamber to give a static CR of 8.5:1, which is a little on the low side for a performance N/A engine (but still way higher than stock.) So I think I'm just going to roll with the CR as it is. It's a lot higher than the original but fairly conservative for an all out performance engine. I could fit some domed pistons to increase the CR but I spent a lot of time modifying the Mahle pistons I already have and ultimately if I want more performance I can just install another more powerful engine. Even with all of the mods it's not going to be a high performance motor by modern standards.

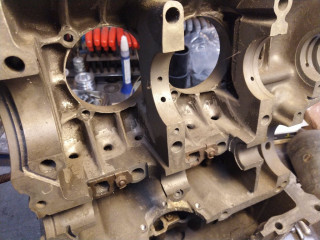

Taking check of everything I still have some work to do before it's ready. It looks like I only machined one of the 40hp barrels to length, which leaves another three to do. Machining the barrel was a complete PITA. I need to make a new mandrel before I attempt the others. I also need to finish dressing the case. I'm about 90% done on one half - knife edging the gussets and adding in additional oil drainage holes and flowing the bearing saddles to help windage.

One factor with the engine choice, is that with a 36hp based engine installed there is still a potential opportunity to run in a tarmac based event and get my 1 hat, however using a 36hp based engine one issue I found is that the exhaust is a different dimension from later engines. The 36hp engine is a lot narrower than its later counterpart, so the Sebring exhaust that I'm making cannot be interchanged between engines. This is another factor in making a decision about the engine as it directly affects the exhaust which is what I was working on. Obviously one thing leads to another and that's how I start off on making the exhaust and somehow end up digging out the Okrasa engine. The plan is to get the engine sewn up and then finish the Sebring to suit this engine. I'll just have to make another if I decide to upgrade the engine down the track.

I guess I'll chip away at all of these items as I get time but it's obviously still a way of from being ready. At least I now have a direction.

Oh, and if you have a pair of Speedwell-Okrasa manifolds going spare, let me know. I didn't buy them back when they were available as I made up some custom EFI manifolds to suit the blower setup, but now I'm moving to N/A I'd really like to get hold of a pair.

If you're interested in the engine specs and build I've linked to some of the original build posts below

36hp Challenge K36 Build Progress

36 horse progress

Comments