Supercharging the Lowlight Part 1

One thing that really struck home on our recent interstate jaunt to ReVolks was how damn slow the bus is. I have often joked that when I toured around Europe (also in a 1600 bay window) you would have to go flat out down the hills just to be able make it up the next one. Well somehow the reality of driving a 1600 bus over very long distances had managed to become little more than anecdotal humour. This is a bit of a shame, as had I remembered how painfully slow driving a1600 bus was I might have opted to build something a little larger. After all, as our cousins in the good ole yew ess of aye say... 'there's no substitute for cubic capacity', or is there? Faced with the reality of having to build another bigger engine I opted to take the easy way out. Forced induction!

A buddy of mine (Razor here on VDubber) has been collecting parts and researching adding an AMR supercharger on his 36hp powered oval. Inspired by the 36hp medusa oval he's opted to use an AMR 300 blower on his project. After doing a bit of research of my own, I decided that an AMR500 blower would probably work reasonably well on a stock 1600 engine.

Some guys I knew back in the UK developed a bolt on turbo kit for a stock 1600cc that gave phenomenal results. From memory they managed to get a stock 1600 to run in the 13s by doing no more than bolting a Garret T3 turbo onto a set of custom extractors along with a re-jetted Renault 21 Turbo carburettor onto a stock engine. Of course, this was probably at massive boost which would have done nothing for engine longevity, but it demonstrates that there are massive horsepower gains to be had for relatively little effort. In fact, you can do a modification like this without even dropping the engine out of the car.

All of this should sound very familiar to anyone in the vintage performance scene, bolt on supercharger kits were very much de-riguer back in the 50's and 60's with kits available from the likes of Judson, Shorrock and Pepco. Bolting on a supercharger should be relatively easy once a few things are figured out.

My plan for the conversion is to use the stock 1600 with no other modifications. Eventually I intend to change out the headers to something that will flow a little better but for the initial test I want to see what kind of power gains can be had by simply bolting on a supercharger. For this I will need to get some baseline readings, so at some point I will need to get the bus on a rolling road.

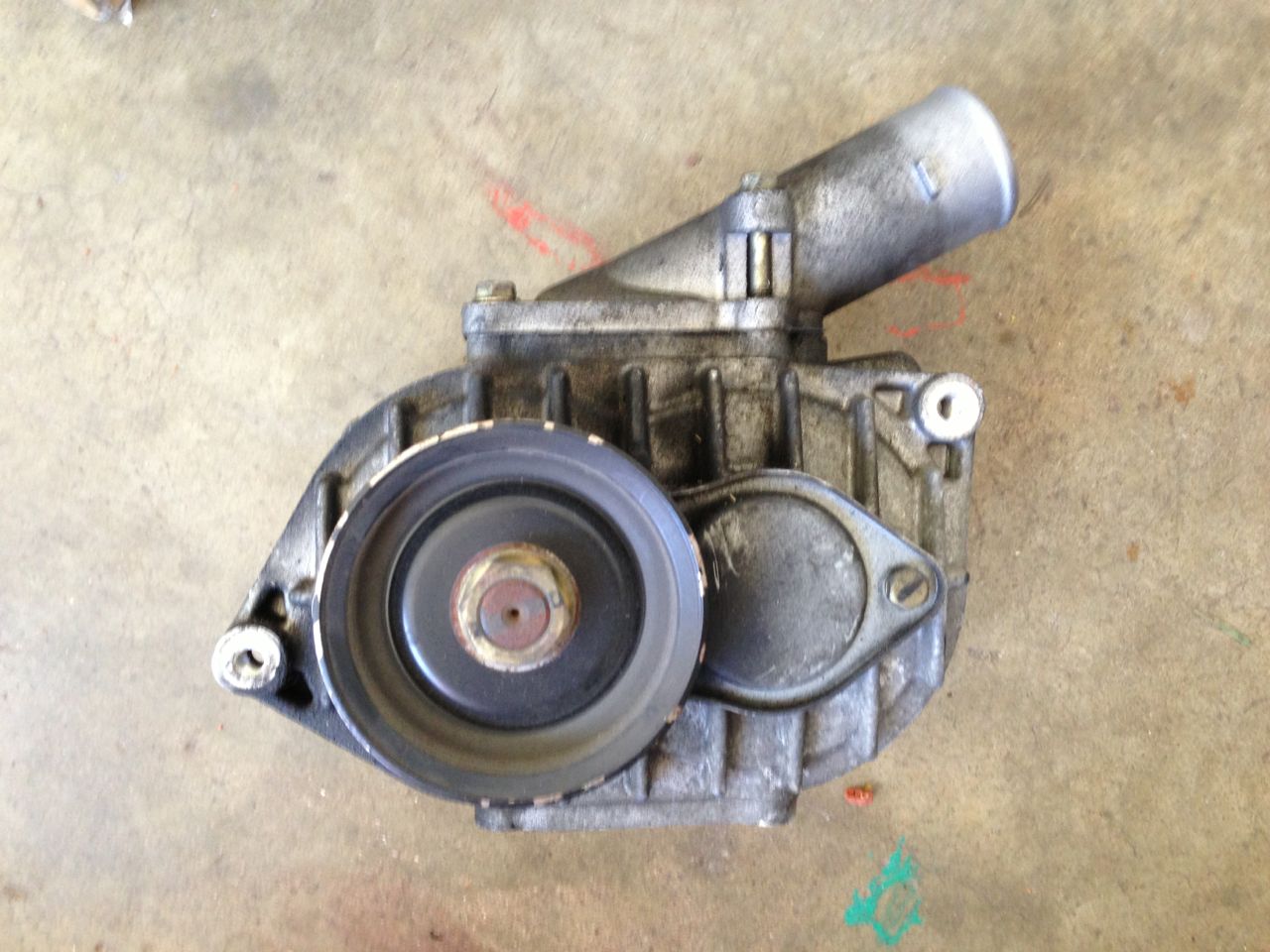

Trying out different supercharger locations on a spare engine

I plan to set the supercharger up in draw through configuration. Originally I wanted to use the stock PICT34 carby as I have only just had it rebuilt but soon realised that I do not have the height to fit it in without resorting to mounting the supercharger in some weird location. The best configuration seems to be to use a side-draft type carburettor. I did a bit of a search for 2" SU's but they are not so common over here in Australia, even EBay did not turn up too much. I did consider robbing one of the SU's off of the Jaguar but decided against it. Instead I decided to use the good ole tuners favourite a Dellorto DHLA40. As luck would have it a sole DHLA40 was ripe for the picking on EBay, so I crossed it off of the wanted list.

I also stumbled across a local guy here in Adelaide. He runs a Jap car business and imports AMR superchargers, he was able to supply me with a pair of blank flanges for the AMR500 along with a vee type pulley and a blank flange for a Weber IDA (Same pattern as Dellorto DHLA - I hope!) Now I have everything I need to be able to make up my own inlet and carby manifolds. The new pulley ratio should give me about 7 or 8 psi when run from the stock diameter crank pulley. This is not an exact mathematically calculated figure but should be in the ball park. There are simply too many variables to consider to be able to calculate it with any accuracy. I figure that it should be a good starting point and if I need to increase / decrease from there I can then look at running a smaller crank pulley for the supercharger.

Power gains should be in the region of double the stock hp rating - 100bhp is not to be scoffed at for such a cheap modification. This is of course dependent on many factors, but a doubling of horsepower seems to be a reasonable expectation from a well set up supercharger modification.

My plans for the drive setup are to use a longer belt to run both the generator (to be replaced with an alternator) and the supercharger. I will use a tensioner pulley to help keep everything in check and stop the belt from jumping. If for some reason I do need to reduce the supercharger speed I will opt to fit a power pulley and a Porsche alternator pulley. This will have the effect of providing a lower ratio drive for the supercharger whilst maintaining a stock fan speed for optimum cooling. If I need a higher ratio drive for the blower I will likely have to look at running a separate pulley and belt for it.

I plan to mount the blower to a custom made mounting that will attach to the stock filler tower mounting bolts. This may also attach to the fuel pump mounting bolts as well. I will likely get rid of the mechanical fuel pump and use an electric one. This is mostly because of space constraints but also to help prevent fuel starvation.

At this stage I am also trying to keep the costs to a minimum. At the moment I am waiting for the Dellorto to arrive. Once that is here I will look to making the mounting bracket and manifolds. There are a few other things that I need to sort out before I can install it but for the most part there is relatively little to do.

If everything works out okay, I might look at manufacturing the parts to sell as a DIY kit. Both with and without the AMR500.

Anyone fancy a bolt on 50 horses??

Comments