With the ReVolks trip looming and the interior in the bus it' time to get things finished off and start packing for the road trip. Everything at floor level is pretty much done, carpet is in, rock and roll seat is in, rear cargo area is carpeted, in fact the only things that havent been done are up in the roof.

The bus has been pretty good over the past week or so, it starts up on the button and apart from a little bit of a flat spot when cold is running pretty good. I readjusted the choke by aligning the (rather small) mark on the choke element housing with the mark on the carburettor, this has made a massive difference but there is still a bit of hesitation when pulling away. This disappears when warm so I'm guessing that I've still got a little tweaking to do.

Since getting the bus roadworthy I've spent the past week and a half cruising to work in it which has been pretty cool. It's great to have a veedub as a daily driver again and even cooler for it to be a bus. It's also given me a chance to iron out a few bugs and make a list of stuff that needs to be looked at.

One of the the things that found its way to pretty much the top of the list was a leaky fuel tank. Ironically when I was originally fitting the engine I looked at the bottom of the firewall tin and noticed that the foam seal looked a bit 'melted', I even thought to myself 'I bet that's due to a leaky fuel tank'. Well, guess what, I knew it! the darn thing leaks. Fortunately Volksfactory once again helped me out from their stash of stuff and provided me with a nice early style fuel tank (early bay tanks have a bolt in style fuel sender unit). I also picked up a few other bits and bobs as well, including a passenger window.

Last weekend was a bit of a milestone in the build with the bus's first trip around the block. One thing that was instantly apparent from the maiden voyage was that the accelerator linkage was absolutely cactus. The second thing that was also readily apparent, and was made a lot worse by the first thing was that PICT34's and 009's do not play nice together. The bus had the infamous flat spot, which made you want to stamp down on the loud button to get things moving. This worked (to a degree) but ended up with the worn throttle sticking in the down (flat out) position. All in all it made for interesting driving.

You might recall from my last blog Paint Your Wagon, that I ordered some parts from MoFoCo, unfortunately they were not posted out so after a bit of chasing up they were finally mailed out to me express. Well according to USPS they should have arrived no later than 5 days later, so after waiting for 6 days I decided to lodge a paypal dispute. The initial slackness on MoFoCo's part, and time limit that PayPal put on making claims pushed me past the point of trying to pussy foot around the issue. I figured that if the parts arrive - all well and good, and if they didn't, then at least I could order them form somewhere else.

So. Spent today fitting the engine into the bus. Had a bunch of shits and bits to fix up like fixing up my dizzy, rewiring for the alternator, fitting a new exhaust, adding the electric fuel pump, running new fuel lines, cleaning red dust from everything. In fact it took most of the day just getting everything to the stage where I could fit the engine.

So, for nearly five years the lovely Lulabelle has been trundling round the festival circuit serving tea, cake and smiles... She is in desperate need of a 1200 gearbox that is compatible with reduction gears....I've had one on order for weeks and they've just rung to say they can't get one...

Can anyone help us? She's been struggling along but I know the original is on it's last legs and probably won't last very much longer...

If you know of anyone that might have one or could source one for us it would be so much appreciated...

So, for nearly five years the lovely Lulabelle has been trundling round the festival circuit serving tea, cake and smiles... She is in desperate need of a 1200 gearbox that is compatible with reduction gears....I've had one on order for weeks and they've just rung to say they can't get one...

Can anyone help us? She's been struggling along but I know the original is on it's last legs and probably won't last very much longer...

If you know of anyone that might have one or could source one for us it would be so much appreciated...

Great!!

Shes a 2L 1975 Kombi and shes very colorful!!

And to tell you the truth, I cant be bothered posting three lots of info about Daisy, so here is her blog http://daisythekombi.blogspot.com/

Feel free to leave comments here or on the blog!!

Had my birthday on monday, got heaps of money for 'Zac's Kombi Fund'.

Hoping to get some new parts for Daisy!!

Managed to spend some time this weekend going through the lowlight and taking check of whats what. The bus was packed to the brim with parts and so it needed to be unloaded to see what parts were missing and what parts needed to be sourced. The bus was supplied with some nice extras such as a roo bar and a spare full width rock and roll seat including the rear matress and all of this needed to be taken out of the bus to be able get in and take a look

Whilst we were making the pop top we did take the time to make up some patterns for the front seats and cut out the material but that was as far as we got. Having not done any form of upholstery before trying to figure out the best way of doing things was pretty hard. Google is pretty good, but even after finding some good videos online there were some details that they just glossed over. In the end the covers just got left and no more was done.

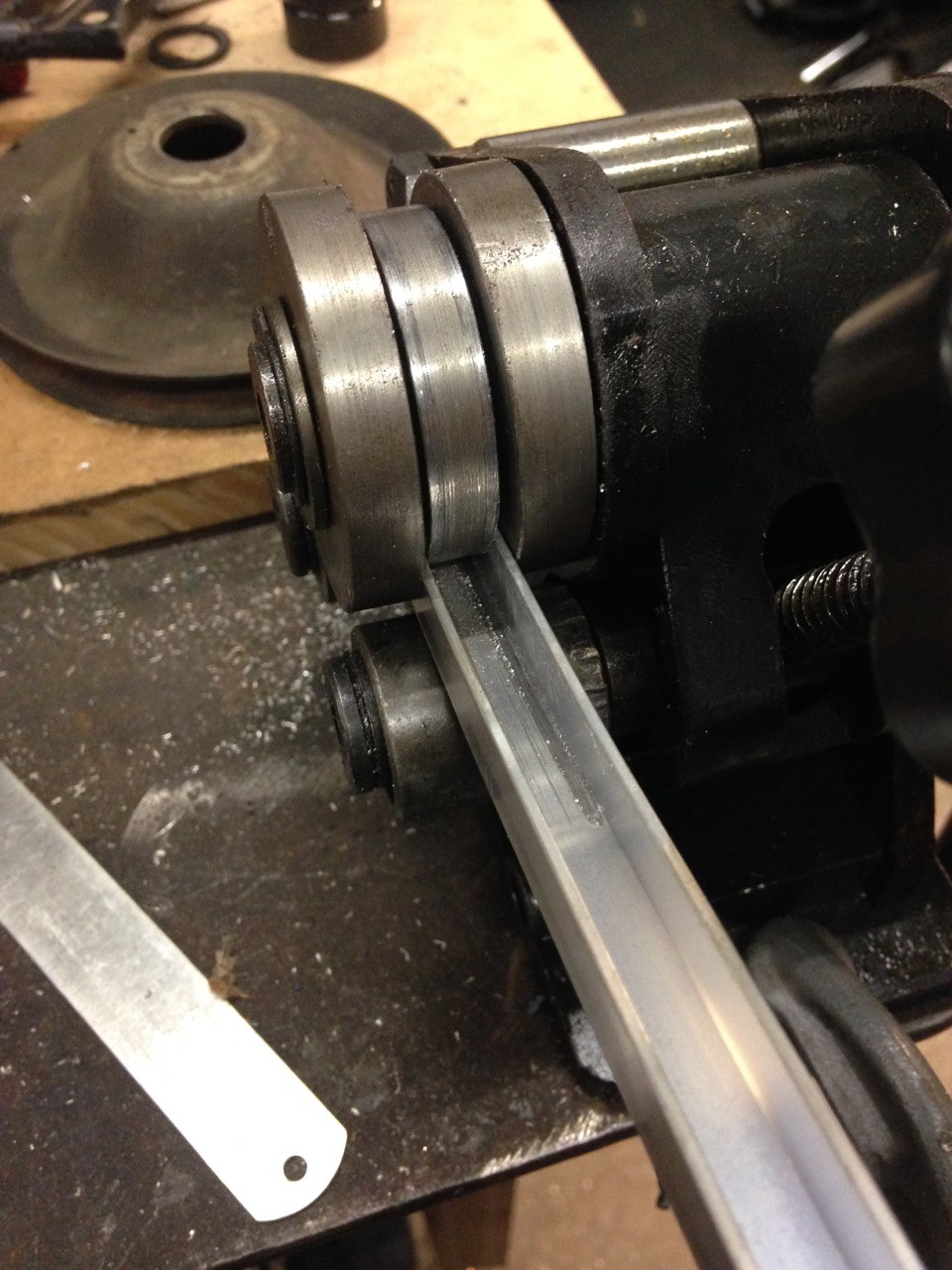

If you follow my blog or have read my previous article DIY Safari frames you're probably aware that I have been trying to roll a curve in aluminium extrusion so that I can make up my own rear safari window for the Lowlight.

Last week the fruits of my labor ended up splitting the aluminium but after doing some pondering this week I realised that the extruded profile was not being supported correctly. The dies that I had made left the edge of the aluminium un-supported which resulted in the profile splitting.

There's a bit of a rust issue with the tailgate on the lowlight which is also causing a bit of a leak and water to get into the bus. The rust is on the bottom of the window under the window rubber so to repair it the rear glass will need to come out. Whilst pondering the best way to fix it I had a great idea - why not replace the rear window with an opening 'safari' window. This way I could make the repair to the rust at my leisure rather than having to get it done in a hurry.

In my lasts blog post Slamfest Part 1 me and the Jimp had stripped down a bay beam and prepped a design for some new side plates ready to cut them out on my CNC plasma. Cutting out the plates was a slow affair as the cutting speed for the 10mm steel plate had to be set at about 300mm per minute, any faster and the quality of the cut suffered. The design was based on a 5 degree castor with the shock tower location moved upwards and backwards to allow for use of the stock shock.

Made a start on building a narrowed beam tonight. Plan is to build two beams - one for my bus and one for The Jimps.

Since building the engine and adding the supercharger the lowlight has been pretty reliable. There were some initial gremlins to overcome such as the vastly underpowered generator, but since swapping it out for an alternator things have been fine. Fine that is until the other day.

We had just stopped off at Hungry Jacks (or Burger King as us Poms call it) to grab some well deserved mango smoothies after a day out at the beach, the bus did not want to fire straight up, which I put down to the very hot weather but I managed to get it started and drove off back to home. We managed to get about 200 yards down the road when the bus just stopped.

Just picked up another project, a 1970 lowlight bus courtesy of @Matt here on Vdubber. I actually bought this several months back but only just got around to picking it up this past weekend. After a bit of a road trip to Mount Gambier and a couple of days with the very hostiptable Tully Family, we towed the bus back to Adelaide to it's new home.

We also brought back a complete roof clip section from another bay for another local Vdubber (splitmeister from AVD). This was strapped to the top of the bus and made the load very top heavy, which made for some 'interesting' driving.

One thing that really struck home on our recent interstate jaunt to ReVolks was how damn slow the bus is. I have often joked that when I toured around Europe (also in a 1600 bay window) you would have to go flat out down the hills just to be able make it up the next one. Well somehow the reality of driving a 1600 bus over very long distances had managed to become little more than anecdotal humour. This is a bit of a shame, as had I remembered how painfully slow driving a1600 bus was I might have opted to build something a little larger. After all, as our cousins in the good ole yew ess of aye say... 'there's no substitute for cubic capacity', or is there? Faced with the reality of having to build another bigger engine I opted to take the easy way out. Forced induction!

It'd been a good many years since I've camped in a bus so I'd really been looking forward to ReVolks. For the non-Aussies here ReVolks is a VW show held in Geelong in Victoria - Some 700k's away from where we are in Adelaide. The mad rush to get the lowlight finished in such a short period of time was mostly so that we could take a bit of a holiday and take in the ReVolks show at the same time.

This weekend I managed to get a bit more done on the Lowlight. After rebuilding the heads last week I decided that I should really split the case and at least take a look at the bottom end to make sure that there were no gremlins in there. Whilst this will add a week or two to the build at least I will get a peice of mind until I get around to building a 2150 for it.

This weekend saw the kombi roof that I brought back from Mount Gambier go off to its new owner. Andrew, the guy that bought the roof, also had various kombi bits that I needed so he dropped them off at the same time. Andrew is a top bloke and was the person kind enough to loan me the trailer to pick the Kombi up on in the first place.

Last night I spent half hour out in the garage going over the fasty engine that I have spare. I want to use the 1600 barrels and pistons (and maybe heads) on the 1300 bus engine that I have.

To determine the condition I did a compression test but his was not really conclusive as I could only turn the engine over by hand which didn't really give a suitable reading. Not deterred i decided to take the heads off and inspect them instead.

Great news. Just got back from Regency after registering the bus. Fortunately there was an old rego sticker still on the windscreen so I was able to fill out the rego form with the old details and get the bus registered. Now all I need to do is get the engine finished off and the brakes overhauled. I also ordered a personalised plate too. :D

Been working pretty hard on getting the bus engine fixed up this weekend. After stripping the old fasty engine down and cleaning the barrels and heads ready for reconditioning, I decided that I would tear down the 1300 in readiness for it's new parts. I also wanted to get all of the tin off of the engine so that I could paint it.

Not updated the blog for a week or so, but that doesn't mean that I've been idle, just too busy to be able to get my thoughts translated into the electronic ether.

Last weekend I spent some time getting the doors prepped ready for painting. The front doors both needed painting, both having been partially prepped. The passenger door was already mostly done with only a few minor blemishes requiring attention but the drivers door needed a fair amount of work. The drivers door has at some time been badly dented and could ideally do with a new door skin, but in a bid to get the bus on the road I decided to see if I could make it a little straighter then it was.

Took a few days off in the week to get some more stuff done on the lowlight. My target for this week was to get the brakes finished off, get the gearbox in and paint the front doors. As I had already done most of the brakes there was only the front nearside left to do and change out the rear flexi hoses and shocks.When I removed the front nearside drum I was met by a bit of a surprise, the brakes were missing. There had been a Burnley.

Was stoked to get a text message today from MelleMel. In it was a photo of my new rego plates for the lowlight. See if you can spot the mistake...

Decided to sort out the brakes today. I had already ordered new shoes, cylinders, hoses and master cylinder, and whilst waiting for the remaining engine parts to arrive thought that it would be a good idea to fix up the other things on the todo list.

Had a bit of a result this week, finally managed to source the remaining parts that I was looking for. If you've been reading the blog you would know from this post that I've been searching high and low for some bukhead tin for a 1600 lowlight. Well as luck would have it, a bloke called Gary replied to one of my wanted ads and said that he had most of the parts that I needed. After taking trip out to go though his stash of parts i walked away with a whole bunch of goodies. Not only did I get the bulkhead tin, but I also got a pair of air vents, a pair of seat trims, a grab handle and a nearside sill repair panel.