Went and picked up the interior for the Ghia today. Gotta admit, I'm well pleased with the job they have done.

If you've been following the build of the Ghia you may recall that I previously blogged about narrowing the IRS arms to help fix a tyre clearance issue that I have with the Ghia. Well having sourced another set of IRS A-arms some time back, this weekend I finally set about getting started.

To get the Ghia through the engineers inpection I need to address the issue of tyre to arch clearance. It had been noted by the engineer that I need to increase the clearance by approximately 10mm. There are a number of ways of acheiving this, most of which I have considered at some point, but all of which have some kind of compromise. My plan was to cut back the inner lip of the wheel arch and raise the suspension a little, but his was far from ideal. However, given the alternative - narrowing the IRS arms, it was the easy option.

As with assembling most things, whether an Ikea flat pack, or a classic car, the order in which things are put together is pretty important. This is especially true of the Type 34 interior.

It’s been a few weeks since I posted a progress update, not because I’ve not done anything, but simply as I’ve been too busy to be able to to spare the time to blog about it. If you’ve been checking my photo stream you would have noticed that I did manage to upload some pictures of what I’ve been up to and you would have noticed that the build is ticking along nicely.

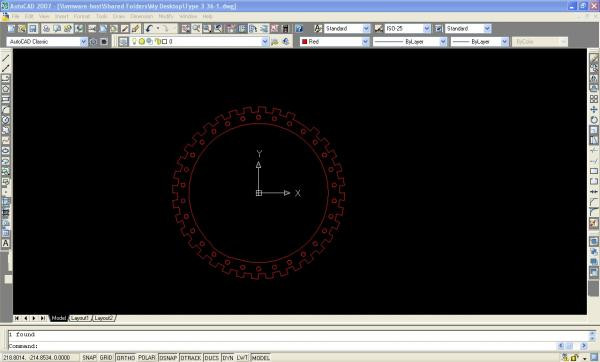

If like me you have wondered how or where you can mount the trigger wheel for your EFI Type 3 engine, well ponder no longer, the answer is here :D

Rawhide references aside, this weekend broaches yet another milestone in the build. For the past 5 or so years the car has sat on axle stands whilst I tinkered about with different suspension setups, but now, after deciding to postpone my plans for the crazy suspension and fitting a stock (ish) IRS setup, it finally stands on it's own four wheels again.

The weekend I turned my attention to getting the rear brakes sorted out. The new backing plates and hub centres finally arrived from the states and so I could fit them up and check out clearances and offsets.

This weekend I turned my attention to getting the rest of the brakes installed. The pedal assembly needed to be fitted and the SACO hydraulic clutch kit installed. The SACO kit replaces the clutch cable with a hydraulic setup which includes a small master cylinder that locates inside of the 'transmission' tunnel, and a slave cylinder that mounts where the stock clutch cable normally mounts.

I finally finished off the engine mounts today. I decided to bolt them in rather than weld them in, mostly as I feel that it will be a lot stronger. To do this I fabricated a plate to fit on the inside of the engine bay tin. This helps spread the load out and reinforce the panel. It will also prevent the bolts from pulling through the metal.

I’ve been pretty busy the past few weeks, so much so that I haven’t even had a chance to blog about what I’ve managed to get done. I’ve really been getting a push on to get the car ready for the 50th anniversary celebrations that we are having in September, and so have been flat out at every opportunity.

With the 50th anniversary event slowly creeping up, I’ve got a renewed enthusiasm for the Ghia and I’m managing to get quite a bit done. This weekend I set myself the task of getting the engine in the car as a trial fit so that I could look to fabricate some engine mounting brackets up. To make the job easier I decided to strip all unnecessary weight off of the engine both to make fitting it easier, and also to improve access around the engine bay. Removing the tin will also allow me to clean, prep and paint it in readiness for the new engine build.

I’ve made some good progress on the Ghia the past couple of weeks. After assembling the IRS last weekend, I stripped and painted the front beam. The front beam was already partially stripped having been removed from the car some time ago. I had previously prepped and painted the steering box and had already removed the hub assemblies too.

Managed to spend some time on reassembling the rear suspension this past weekend. The paint I applied last weekend has not come out too bad, but the issue I had with the thinners reacting has left a bit of a mottled finish. But, as I’m now on a mission to get the car back on the road by September it’s just something that I will have to live with. Mind you, it’s really not too bad, and it is one of those things that will not really get scrutinized. (in reality it will not even get seen), or maybe I’m just trying to convince myself so.

Well, it's been a little time since I actually did some work on the Ghia, recovering the interior doesn't really count as it wasn't me doing the work. So spurned by an invitation to the Victoria day of the Volkswagen in November (Cheers Grey54) I've decided that I will try and get to the event - especially as I was also invited last year, and truth be told the Ghia is pretty much int he same state as it was back then.

I found out a funny thing today - my old silver '69 Ghia was originally an electric sunroof version that was painted cobalt blue with a black roof. The current owner fond out this info by sending off for it's birth certificate. This is pretty astonishing news - as had I known this - I probably would never had sold it. '69 Type 34's are pretty rare - sunroof models even rarer!

Spent a bit of time yesterday stripping down the Type 3 IRS that I will be fitting into the Type 34. This came out of the fastback doner car I bought a few months back. The suspension is in pretty good shape with no rust, dings, modifications or bits missing.

Well I managed to find someone to supply the Porsche parts that I need, so far I've picked up the wheels from him (a set of 16" Fuchs with a space saver spare), and hopefully this week I should be able to pick up the suspension and brake parts. The swing-axle rear end has been removed, and sold. The IRS axle has been trial fitted to allow me to measure for the positions of the engine and gearbox mounts, but I think I'll wait until the 944 'A' arms have been fitted before I get the welder out.

I managed to source a pair of headlights with trim rings and bowls, they're not original parts, but the difference is only slight, the complete cost was only £30. The headlights are exactly the same as the ones I fitted to Karens Ghia after it was imported, those cost £80 for the lights alone.

I've also bought myself a larger compressor so that I can blast and paint the underneath of the pan, there's a lot of prep work to be done under there, taking off all of the old paint, and blasting all of the surface rust away.

Once the rear end is sorted out, and the suspension is in place with the engine and gearbox mounts welded up I think I'll turn my attention to the roof. There's a lot of prep work to be done carefully removing the roof skin from the roof frame. I have already trial fitted a sunroof motor that I bought from the scrap yard, but the motor seemed to run too fast, it was way too awkward without the roof on the car, so it may be best to sort this out after the roof is fitted. I'm going to try to get as much prep work done as possible before the car is sent off to the boys at Paintbox as this will make their life easier, and possibly be a bit easier on the pocket as well.

I have been building my Type 34 Karmann Ghia for the past 12 or 13 years (it's been so long I've forgotten when I actually bought it).

So far the restoration has been documented on my personal website www.t-34.co.uk or over at the Type 34 Registry (ww.type34.org) where I help manage the site.

The current status is that the engine and gearbox are built and ready to fit, the car has been repainted, the suspension and brakes have mostly been finished and the interior is currently at the trim shop being recovered.

The only major works left to do are to get the engine and box back in the car, which requires finishing off the rear suspension and plumb the engine in

The engine is based around a Type 4 Unit and runs at 2.7 litres on a set of LN Engineering nickies. This is fueled by a turbo / EFI setup runnning from a DTA EFI unit. The engine drives a Porsche 915 5-Speed through a 944 rear suspension setup and has 996 / 944 turbo brakes all round.

If you are into Type 34 Karmann Ghia's, chances are that at some point you would have come across the name Mick Percy. If the name sounds familiar to you it's probably because you have spent some time over at Type34.com or as it's more commonly known The Type 34 Registry where Mick has been the resident webmaster for the past ten years. You might also know him from right here on VDubber.

The build of Mick's '65 Sunroof Type 34 spans some 18 years, two continents and several changes in direction.

Here's Mick to tell you a little more ...