If you've been following the build of the Ghia you may recall that I previously blogged about narrowing the IRS arms to help fix a tyre clearance issue that I have with the Ghia. Well having sourced another set of IRS A-arms some time back, this weekend I finally set about getting started.

To get the Ghia through the engineers inpection I need to address the issue of tyre to arch clearance. It had been noted by the engineer that I need to increase the clearance by approximately 10mm. There are a number of ways of acheiving this, most of which I have considered at some point, but all of which have some kind of compromise. My plan was to cut back the inner lip of the wheel arch and raise the suspension a little, but his was far from ideal. However, given the alternative - narrowing the IRS arms, it was the easy option.

As with assembling most things, whether an Ikea flat pack, or a classic car, the order in which things are put together is pretty important. This is especially true of the Type 34 interior.

It’s been a few weeks since I posted a progress update, not because I’ve not done anything, but simply as I’ve been too busy to be able to to spare the time to blog about it. If you’ve been checking my photo stream you would have noticed that I did manage to upload some pictures of what I’ve been up to and you would have noticed that the build is ticking along nicely.

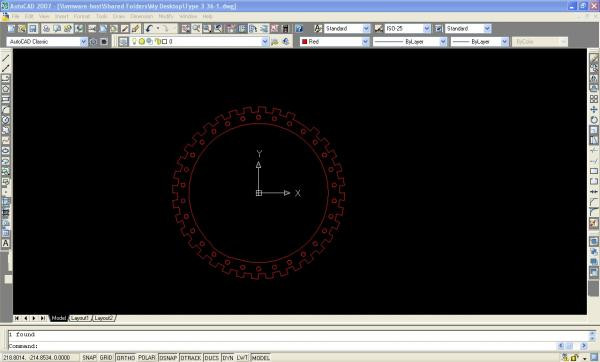

If like me you have wondered how or where you can mount the trigger wheel for your EFI Type 3 engine, well ponder no longer, the answer is here :D

Rawhide references aside, this weekend broaches yet another milestone in the build. For the past 5 or so years the car has sat on axle stands whilst I tinkered about with different suspension setups, but now, after deciding to postpone my plans for the crazy suspension and fitting a stock (ish) IRS setup, it finally stands on it's own four wheels again.

The weekend I turned my attention to getting the rear brakes sorted out. The new backing plates and hub centres finally arrived from the states and so I could fit them up and check out clearances and offsets.

This weekend I turned my attention to getting the rest of the brakes installed. The pedal assembly needed to be fitted and the SACO hydraulic clutch kit installed. The SACO kit replaces the clutch cable with a hydraulic setup which includes a small master cylinder that locates inside of the 'transmission' tunnel, and a slave cylinder that mounts where the stock clutch cable normally mounts.

I finally finished off the engine mounts today. I decided to bolt them in rather than weld them in, mostly as I feel that it will be a lot stronger. To do this I fabricated a plate to fit on the inside of the engine bay tin. This helps spread the load out and reinforce the panel. It will also prevent the bolts from pulling through the metal.

I’ve been pretty busy the past few weeks, so much so that I haven’t even had a chance to blog about what I’ve managed to get done. I’ve really been getting a push on to get the car ready for the 50th anniversary celebrations that we are having in September, and so have been flat out at every opportunity.

With the 50th anniversary event slowly creeping up, I’ve got a renewed enthusiasm for the Ghia and I’m managing to get quite a bit done. This weekend I set myself the task of getting the engine in the car as a trial fit so that I could look to fabricate some engine mounting brackets up. To make the job easier I decided to strip all unnecessary weight off of the engine both to make fitting it easier, and also to improve access around the engine bay. Removing the tin will also allow me to clean, prep and paint it in readiness for the new engine build.

I’ve made some good progress on the Ghia the past couple of weeks. After assembling the IRS last weekend, I stripped and painted the front beam. The front beam was already partially stripped having been removed from the car some time ago. I had previously prepped and painted the steering box and had already removed the hub assemblies too.

Managed to spend some time on reassembling the rear suspension this past weekend. The paint I applied last weekend has not come out too bad, but the issue I had with the thinners reacting has left a bit of a mottled finish. But, as I’m now on a mission to get the car back on the road by September it’s just something that I will have to live with. Mind you, it’s really not too bad, and it is one of those things that will not really get scrutinized. (in reality it will not even get seen), or maybe I’m just trying to convince myself so.

Well, it's been a little time since I actually did some work on the Ghia, recovering the interior doesn't really count as it wasn't me doing the work. So spurned by an invitation to the Victoria day of the Volkswagen in November (Cheers Grey54) I've decided that I will try and get to the event - especially as I was also invited last year, and truth be told the Ghia is pretty much int he same state as it was back then.

I found out a funny thing today - my old silver '69 Ghia was originally an electric sunroof version that was painted cobalt blue with a black roof. The current owner fond out this info by sending off for it's birth certificate. This is pretty astonishing news - as had I known this - I probably would never had sold it. '69 Type 34's are pretty rare - sunroof models even rarer!

Went and picked up the interior for the Ghia today. Gotta admit, I'm well pleased with the job they have done.

Spent a bit of time yesterday stripping down the Type 3 IRS that I will be fitting into the Type 34. This came out of the fastback doner car I bought a few months back. The suspension is in pretty good shape with no rust, dings, modifications or bits missing.

I have been building my Type 34 Karmann Ghia for the past 12 or 13 years (it's been so long I've forgotten when I actually bought it).

So far the restoration has been documented on my personal website www.t-34.co.uk or over at the Type 34 Registry (ww.type34.org) where I help manage the site.

The current status is that the engine and gearbox are built and ready to fit, the car has been repainted, the suspension and brakes have mostly been finished and the interior is currently at the trim shop being recovered.

The only major works left to do are to get the engine and box back in the car, which requires finishing off the rear suspension and plumb the engine in

The engine is based around a Type 4 Unit and runs at 2.7 litres on a set of LN Engineering nickies. This is fueled by a turbo / EFI setup runnning from a DTA EFI unit. The engine drives a Porsche 915 5-Speed through a 944 rear suspension setup and has 996 / 944 turbo brakes all round.

My whole intention with building this car may seem a bit sacrilegious to some, but the one thing that Volkswagens have always been lacking in is power. It is for this reason that I intend to build one of, if not the fastest T34's around, (I'm not really a boy racer, I've just decided to take my mid life crisis a bit early). Most of what my plans include will not permanently change the structure of the car, and so if I decide, it could easily be changed back to original.

The only major structural change I will make is to change the roof for one with a sunroof in, but then again I'm sure that most people wouldn't object to that (except the true purists). I had a bit of a lucky chance meeting with one Clive Richardson, now the Type 34 secretary (I think) of the Karmann Ghia Owners Club, who owns a very tidy RHD sunroof model. It was at one of the infamous Karmann Connection swap meets, I spotted his car and decided to go and have a chat with him. It was whilst in conversation with him I mentioned; "wouldn't it be great if you could get a complete roof..........", well the gods must have been smiling at me that day, as Clive then told me how he had bought a complete roof from someone in Germany, so as he could get the electric motor to replace the faulty unit in his car, what was more was that he was prepared to sell it. We struck a deal and Clive even delivered it to me.

The real heart of the project is the motor, a 2.3 Litre Type 4 unit, with a Ray Jay 0.8 AR turbo, and a 50 HP Nitrous kit. I've done lots of research on All aspects of turbo charging, and nitrous injection, and feel confident that I could get a very fast reliable motor together. (I met a guy from Sweden who ran a road legal home grown bug, which he used for strip racing, he ran well into the nines using a 2.3 Fuel injected turbo'd Type 4 motor, with a hybrid Garret T3 exhaust/T4 compressor turbo,).

The key to any turbo charged engine is to have a good fuel delivery system, and where most designs reach a limitation is their use of carburetors. It was once said that it was impossible to run a blow through system on anything over 5psi, although this 5psi rule has been proved wrong (Lotus Esprit Turbo's used just this method successfully running boost pressures of 12psi), both methods of carbureted turbo induction have their drawbacks. The biggest problems are fuel enrichment under boost conditions, and fuel separation within the inlet manifold. Carbs don't really have a good proportional control band, and tend to provide a very unreliable response when used in this application. (Remember a turbo engine running too lean on boost will burn out valves in an instant. Also as any air-cooled owner will vouch, when it gets cold carbs begin to ice up, can you imagine how quick this would happen in a suck through system, where rather than having an induction pressure of say 1-2psi you are running at 16.

The best way to deal with this problem is to use fuel injection, some units also benefit from a host of other features, such as extra injector control for boost enrichment, water injection or nitrous applications, soft rev limits, shift lights, boost control, switch-able program settings that can be changed `on the fly`, nearly all systems use a wasted spark type ignition system, this coupled with the crank triggers that these systems use means that you can chuck your inefficient distributors away. It is a well proven fact that bottom end power gains are over 25% better than using carburetors, how do you think that they can get a 1.25 Litre fiesta to go so fast? (sic).

One of the best systems that I've seen is the Haltec E6 unit, although I don't think that they have any distributors in this country, (I think it's an Australian company). I did at one time think of making my own system using an early Ford Sierra Cosworth brain, (the brain only controls the fuel injection, and not things like ABS, traction control etc. as most other OEM brains do). However although software is available to program the chips for these units, its much easier to get an after-market unit where you just plug your laptop into the brain, download a preset set of injector timing parameters, and tune them up as you drive around, (not all of us have a rolling road in their garage).

Nitrous sounds like a scary thing to have on a turbo motor, but truth be told its not used the same way as with a normally aspirated engine, the nitrous is only active up until a certain boost pressure, (full boost or just below) this in effect gets the engine up to boost quicker and eliminates any turbo lag, it is possible to keep the nitrous switched in when full boost is achieved, which is fine if you complete professionally and tear your engine down after every pass, however I don't think that it is a viable proposition to use it this way in a street motor. (engine life expectancy-One day if you're lucky). One great advantage that nitrous provides for turbo engines is that it considerably lowers the charge temperature, practically super cooling the air entering the engine, which is great news as turbo charged engines run phenomenally hotter than normally aspirated engines. Because of the way that the nitrous is used it also lasts considerably longer than in other applications.

The particular turbo that I am using is a bit oversized for a 2.3 Litre engine,(0.8 AR), whilst this gives very good high end power, it does also create a lot of turbo lag, which is where the nitrous helps out, eliminating the lag so that it spins up quicker. The higher RPM gains with a larger turbo mean that whilst most smaller Turbo's compromise their high end operating range to eliminate lag the larger unit will provide more power further up the rev range.

One modification that I intend to do but have not been able to find out too much about, is to fit a Porsche 5 speed, there's no way that I'm paying the extortionate prices that they want for a Berg 5 speed,( after all its still a VW box, and they're not that strong). Volksworld did an article once, but it wasn't really that informative, they told you how to reposition the gearbox mounts so that the gearbox would mount into the frame-horns of a swing-axle Beetle, but no mention was made of what drive shafts you should use, or how they needed to be modified, I can only assume that you had to cut and shut a Porsche inner with a VW outer to get the splines correct to match up to the hub. Although this sounds extreme I did have some drive shafts converted like this before, and they ran fine. If anyone has any info, then please let me know.

There is one cat that I am definitely not going to let out of the bag, that is my plans for the front suspension, think steering box, think not. All I will say is full height and camber adjustment, rose-jointed.......................

Well, I'm all excited now, I think I'll go and take the angle grinder to the roof.

I've been doing some research on suspension and steering geometry and have come across a couple of nice programs for calculating suspension dimensions. Although this is not a completely scientific art, it certainly takes out the hard math's aspect, out of calculating things like roll centres, wheel scrub and dynamic camber/castor changes.

I've made a basic design for the layout, all I have to do now is see if it will fit, unfortunately things are not looking good as I was hoping to retain the original frame horns, and it looks like it will lengthen the wheelbase too much if I try to fit the suspension in the position where the beam originally was. I guess if that's the case, I'll have to decide if I can justify cutting the frame horns off, I suppose I could always get another pan.

It's been long overdue but I've had to get on with doing some decorating in the house, (unfortunately the '65 is not at the top of my list of priorities at the moment). The parts amassed for it had to be moved as I am soon going to be knocking down the wall that they were resting against. This meant that I finally had to get around to assembling the racking that I had got for the garage, (it's only been sitting there for two years!), but I'm glad that I did, not only has it given me enough space to carefully store all of those parts, but it's given me space to store all of those things that were cluttering up the garage. Next thing is to chop down the tree behind the garage, as I'm sure that soon it is going to cause the back wall to collapse. Too many things....not enough time....

Here is the TUV Birth Certificate for the '66, as you can see it was in fact built in '65. This has put a bit of a spanner in the works, so to speak, as I had assumed that the registration number that came with the car was genuine, ( LHU 211E - 1967 ? ), and I would have liked to have kept it. As the DVLC went computerized in about 1983, they have no records dating to before that date, ( I guess someone must have eaten them), so if you have a car that has been off of the road since before then, as I have, they will have no record of it's proper details. This is not a problem, as there are two things that you can do: If you know the registration number, and it has not already been reissued to someone else, you have to supply them with some proof that the vehicle is of historic significance, and deserves to keep the number, (a letter from an approved car club such as the KGOC, is all that is needed), and then it can keep it's proper registration number. If on the other hand you either don't know the number, or cannot get a letter of approval then an age related plate will be supplied. This is one that bears the correct suffix for the year, but was not necessarily the one originally supplied with the car.

I think that I will end up with an age related plate, which is a shame, but it doesn't seem realistic to think that the above registration is correct, although, I suppose it is possible, that the car was not registered for two years. I think that I would prefer to have an unoriginal registration that is correct for the year, as I doubt that I would be able to find out what the original number was.

I have sent off for my age related registration number, which will have a "C" suffix, indicating 1965. As some of you have pointed out; the car would have been a 1966 model year and was probably not registered over here until 1966. But as far as DVLC are concerned, as it states on the TUV birth certificate that the car was sold in 1965, they are not prepared to issue a later registration. This is understandable I guess. Rules are rules.

I'm not particularly bothered, obviously I would have preferred to have kept the registration number that was originally issued to the car, but I have no way of finding this out.

I'll keep you posted on the outcome.

Well I managed to find someone to supply the Porsche parts that I need, so far I've picked up the wheels from him (a set of 16" Fuchs with a space saver spare), and hopefully this week I should be able to pick up the suspension and brake parts. The swing-axle rear end has been removed, and sold. The IRS axle has been trial fitted to allow me to measure for the positions of the engine and gearbox mounts, but I think I'll wait until the 944 'A' arms have been fitted before I get the welder out.

I managed to source a pair of headlights with trim rings and bowls, they're not original parts, but the difference is only slight, the complete cost was only £30. The headlights are exactly the same as the ones I fitted to Karens Ghia after it was imported, those cost £80 for the lights alone.

I've also bought myself a larger compressor so that I can blast and paint the underneath of the pan, there's a lot of prep work to be done under there, taking off all of the old paint, and blasting all of the surface rust away.

Once the rear end is sorted out, and the suspension is in place with the engine and gearbox mounts welded up I think I'll turn my attention to the roof. There's a lot of prep work to be done carefully removing the roof skin from the roof frame. I have already trial fitted a sunroof motor that I bought from the scrap yard, but the motor seemed to run too fast, it was way too awkward without the roof on the car, so it may be best to sort this out after the roof is fitted. I'm going to try to get as much prep work done as possible before the car is sent off to the boys at Paintbox as this will make their life easier, and possibly be a bit easier on the pocket as well.

Wow Looking at the date below, it's been some time since I've been to this page. So I guess in two years a lot must have been done (yeah right). I've managed to source some more bits, these include a NOS type 4 engine case, a Porsche 915 gearbox (from an '83 911 SC), a tacho, an IRS rear end and some other bits and bobs. The remainder of the chroming has been taken to the chromer's, all that remains is some catches and other bits that are to be zinc plated. I've started to strip out the remainder of the shell in readiness for it's trip to the painters (I've decided to entrust this to the professionals, plus I never seem to get the time). The boys from Paintbox have been round and had a look, and say that the roof shouldn't be a problem (they're experts at roof chops on bugs) so I need to get it ready for when they can fit it in, which should hopefully be sometime late August. This involves removing everything that's left on the car, and doing a bit of tinwork (I have to fabricate some engine mounting points, as the original top style mount will have to be removed, and a bus style (or later type 3 style) cross-member needs to be fabricated. to do this successfully the engine and gearbox needs to be trial fitted, (this will also allow me to weld the mounts for the Porsche gearbox cross-member as well).

The gearbox needs an overhaul as the synchro-mesh on first gear is shot, I have the parts to do both first and second synchro's and have been informed that it's a relatively easy job. This however is not the first job on the list, that job is to clear out the garage, which has been neglected for quite some time, as I need to create enough space to work on the Ghia (plus Karens Ghia is due back from the painters soon). So come tomorrow that's what I'll be doing.

Next on the agenda is to remove the old swing axle suspension and replace it with the IRS unit. At the moment I'm looking for a 944 rear end so that I can transfer the aluminum trailing arms and hubs / disc brakes onto the IRS unit. This is practically a straight swap - evidently even the torsion bars can be used.

Then the front suspension will get overhauled, again 944 / 968 hubs and brakes are going to be fitted, the best option is to go for the later units as they utilize a four pot caliper and larger discs, but this limits you to fitting 16" or larger wheels, and all of the best Porsche wheels are 15".

Other commitments have meant that as usual progress has been slow, I've picked up a SACO hydraulic clutch kit which looks like a good quality item - It's pretty much a necessity as I'm sure the standard VW pedal / cable would not be up to the job of operating the Porsche clutch.

I have had someone give me a quote for painting the car which is a reasonable price so I'm gonna get him to paint it for me. As usual my work commitments are meaning I'm getting less time to work on the car and do this kind of stuff myself.

I've decided to remove the old how-to's from the site. The Type 34 Registry has now opened its doors to all without subscription, they have a far wider range of articles so I decided my few tech articles were no longer worth having. I've also added a link to a site called 'The air-cooled multimedia maintenance manual' this covers all aspects of keeping your VW engine in shape. I'm sure for all of you looking for maintenance tips the answer to your questions can be found on one of these two sites.

Getting rid of those articles has freed up a little space so I'm considering adding a forum, I've mailed my ISP to see what kind of scripts I can run. Hopefully I can set something up.

I'm trying to go for a change in direction with the site, I'm hoping to get rid of all the stuff which is just generalising and replace it with stuff specific to tuning Type 34 Ghia's and maybe Type 3's - There's far better sites out there that cover the general aspects of T-34's (well there's one - The Registry) so I've decided to kinda 'specialise' a bit more.

Welcome to the new look T-34 site.

It's been some time since I built the site in it's previous guise (December 2004 in fact!), so I decided it was about time to have a makeover. With over 40,000 hits to the site since it first started back in 1999 and about half of those since the last site upgrade, I guessed some people would probably be bored with the way it looked, plus now the Ghia is actually seeing some time spent on it, the site content is getting added to more frequently.

Most of the information available on the previous site has been carried over, a few articles have been dropped, some have even been updated, plus I have added all of the progress reports on the restoration that I could find from the previous websites - just for prosperity's sake. The Gallery has been migrated across so all of the pictures can still be found - although it is now known as the 'Media Library' as it can now contain most types of files, not just pictures.

New Features

With some deliberation, and a bit of a heavy heart, I have decided that after over 10 years of running my http://t-34.co.uk site, I am going to close it down next year.

This decision is mostly due to the fact that i have too many other websites to look after, and getting the time to update and maintain this one is simply too limited. Running Vdubber.com, as well as a variety of other non-Volkswagen related sites, and trying to keep on top of everything generally means that one or more sites suffer.

All is not lost however, as I will be transferring all of the info over to my account here at Vdubber. The blog entries here will get transferred over to my blog, and the images will get transferred to my gallery here too.

Along with this change goes a change of email address too. My new email is mick[#at#]vdubber[#dot#]com This is currently active, so feel free to use it next time you email me.

The interior is finished - Went down to see it today. It looks great and I can't wait to get it home (picking it up later in the week).

I went for a medium grey leather, with matching vinyl panels. The panels also have the correct heat seams in them too.

Will post some pics of the Interior when I get it home later in the week.

Just need to get the thing back on it's wheels again so that I can take it to the trimmers to get the headlining done, unfortunately this will have to wait until the garage extension is done.

I spent this weekend finishing off painting the IRS for the Ghia. I stripped the paint from it last weekend using a combination of paint stripper and a zip wheel in my grinder. There was only some minor surface rust, so I sanded this back ready for painting.

I decided to paint the suspension myself, rather than getting it powder coated, this was mostly due to the shiny finish that powder coating normally gives, I wanted a low gloss almost satin finish to be more like the original.

I had some paint left over from painting the pan and roll cage on the oval so decided to use this. It comprises of an etch primer and enamel based topcoat. I generally favour this paint for chassis stuff as I can thin it with normal meths and don’t need to buy a special thinners as I do with other brands.

I had a bit of an issue with the primer separating out from the thinners, which I put down to it being old paint, this meant going out to buy some more paint and spending a fair bit of time cleaning the sludge out my spray gun.

I got a call from the guy I bought the Fasty off of last week, turns out that another customer had crashed her Type 3 and was on the look out for a doner car. So this weekend I removed the engine and gearbox from the fasty in readiness for it to be picked up.

It's been some time since i pulled the engine from a Type 3, and apart from it being the hottest day of the year, I managed to get the engine and box out of the car in a couple of hours. This included getting in running so that I could reverse it up on the ramps as well.

Fortunately there were no seized or rounded bolts, and the whole process was fairly painless.

Now all I need to do is rebuild it.

With the new engine for the Razoredge now procured, I've been looking towards what I need to do to it to get it up and running in the razor. The engine itself is a standard Type 3 fuel injected unit that is currently still in the '71 fastback in my garage. It leaks a little oil, but runs okay, and shows 80k on the odometer. this could possibly be 180k or maybe even higher, but this doesn't bother me as it runs fine, and I will eventually rebuild it anyway.

The choice of a fuel injected unit as opposed to a naturally aspirated unit is, to me, a no brainer. EFI is far superior in terms of low range power, fuel economy and drivability. Not to mention that they are more efficient than a carburetted engine - this is the reason that pretty much all modern cars are EFI'd - stricter emmissions regulations mean that higher efficiency is needed.

But anyway - I digress. I say that a fuel injected engine is better - but this is not regarded as the case for the Type 3. Over the years the L and K jetronic systems have come into a lot of bad press, especially amongst those who maintain thier own cars. The system is hard to diagnose issues on, as there is no diagnostics funtions available to assist in determining what's wrong. Fixing a faulty system is really a case of eliminating all possibilities, one by one, until the fault has been found. There is no laptop port to plug in your laptop, and get an instant readout of what is going on, and to many, this means that the system is considered complex and unreliable.

As I blogged about previously. the other main issue with the stock fuel injection systems is that they are not tunable. There is no way to modify the injector 'maps' to account for even simply modifications, such as fitting an extractor system. Change something on the system and it cannot compensate. Modern systems can overcome this. Either by closed loop feedback, from a lambda sensor, or by simply having the ability to be reprogrammed. This is the main reason that I want to utilise an aftermarket system, plus it is more suited for adding a turbo to later down the track.

I plan on using a distributorless system. this means adding a crank or distributor trigger, and utilising a coilpack instead of a distributor to take care of the ignition side of things. Distributorless systems have a couple of advantages over normal distributor controlled systems. Firstly, there is no electrical 'switch' in the HT (high tension) circuit, it has a direct lead from the coil to the spark plug. This means a stronger spark, and no degredation over time (wear). The other advantage is that the systems generally work in what is called a 'wasted spark' mode. This means that for a four cylinder engine, there are only two coils. This means that they fire twice each cycle, once on the ignition, and once on the exhaust stroke. The firing on the exhaust stroke brings a massive advantage, it helps scavenge the cylinder by ignighting any unburned gasses. All of this together generally means, more efficiency, and in turn, better performance.

Regular readers of my blog will know that the Type 4 engine, and Porsche 911 gearbox that I have built for the Razoredge has been borrowed for use in my salt flat race car. Whilst pondering on how much grief it would be to get it installed in both the Oval and the Ghia, and be able to swap them over without too much of an issue, I came to the conclusion that it was simply too much hassle.

Whilst I had always dreamed of the big Type 4 powered Type 34. Now, after some 15 years of building it, and having moved to a different country, I've decided that I simply would like to get it on the road. There's no point in having a fast road car here in South Australia. There are no drag strips, very few race tracks, and with cops that hide in bushes with radar guns, little point in having a 350hp Type 34.

So I've decided to fit a stock IRS, gearbox and EFI engine,so that I can complete the car and get it on the road. And whats more, I've even sourced a Fastback to act as the doner car.